I recently watched the movie, “Bluffmaster”. The movie features a Jade black 1969 Mustang GT convertible.

1969 is the year Ford introduced quad headlamps (four sealed beams) in the Mustang. 1969 was the only year in Mustang's history when four headlights were used. The outer lamps had chromed bezels, not painted ones anymore and the inner lights, set in the grill had overhanging shrouds.

MP 09 means the car is registered in Indore, Madhya Pradesh.

|

The hood (bonnet) was locked with standard stainless-steel pin-style hood locks. Note the original Mustang flat-black non-reflective paint on the hood and the dummy hood scoop. |

| Parking lights were now built in, replacing the earlier round-style. Note the standard hood without the dummy GT scoop. |

The convertible and the hard-top had distinctive rear-facing exhaust trim on the quarterpanel.

| This Silver Jade convertible is not from the movie. It is also wearing the GT style Magnum 500 wheels. |

The centre console was standard on all 1969 Mustang convertibles, i.e. both the type 76A convertible and the type 76B convertible with deluxe interior.

|

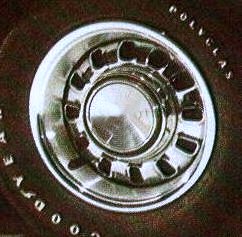

The Black Jade convertible in the movie, "Bluffmaster" has the styled steel wheels with stainless steel trim rings and plain center caps. |

hood (bonnet) was locked with standard pin-style hood locks. Note the original Mustang flat black paint on the hood.

Love the flat-black non-reflective paint on the 'Stang's bonnet (hood) and dummy scoop..

T)

200 cubic inch (3,273 cc) straight six engine with 1 barrel carburetor,

developing 115 bhp

@ 2800 rpm and 190 lb. ft. torque @ 2400 rpm.

This engine could use

regular petrol. There was no air-conditioner with this engine.

L) 250

cubic inch (4,089 cc) straight six engine with 1 barrel carburetor,

developing 155 bhp @ 4000 rpm and 240 lb. ft. torque @ 1600 rpm.

This engine could use regular petrol.

F) 302

cubic inch (4,942 cc) V-8 engine with 2 barrel carburetor, developing

220 bhp @ 4600 rpm and 300 lb. ft. torque @ 2600 rpm.

This was the smallest V-8 and could use regular petrol.

G) 302

cubic inch (4,942 cc) V-8 engine with 4 barrel carburetor, developing

290 bhp.

This engine had to use premium petrol

only.

It powered the famous

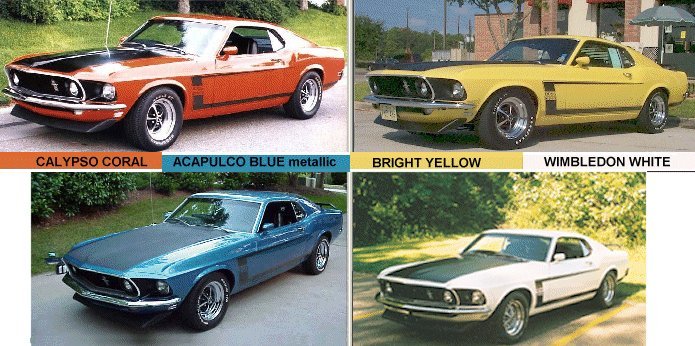

1969 baby Boss 302 Mustang. This very hot car, styled by Larry Shinoda came only in four fancy primary colors

It had an electronic RPM limiter that shorted out cylinders at 6,150 rpm.

H) 351 cubic inch Windsor (5,766 cc) V-8 engine with 2 barrel carburetor, developing 250 bhp @ 4600 rpm

and 355 lb. ft. torque @ 2600 rpm. This engine could use regular petrol.

M) 351 cubic inch Windsor (5,766 cc) V-8 high-compression engine with 4 barrel carburetor,

developing 290 bhp @ 4800 rpm and 385 lb. ft. torque @ 3200 rpm.

This engine had to use premium petrol only. This new 351-inch engine went into the new 1969 Mustang Mach 1.

It had the famous "shaker" scoop that projected through the hood.

S) 390 cubic inch (6,384 cc) big-block V-8 high-compression engine with 4 barrel carburetor,

developing 320 bhp @ 4800 rpm and 427 lb. ft. torque @ 3200 rpm.

This engine had to use premium petrol only.

Q) 428 cubic inch (6,990 cc) Cobra-Jet V-8

high-compression engine with 4 barrel carburetor, developing 335 bhp @ 5200 rpm and 440 lb. ft. torque @ 3400 rpm.

This engine had to use premium petrol only.

R) 428 cubic inch

(6,990 cc) Cobra-Jet V-8 high-compression engine with 4 barrel carburetor,

developing 335 bhp.

This engine had to use premium petrol only. Though it was also a 428 cid engine, it had larger-valve heads and a race-brewed intake

manifold. It also had ram-air induction and a functional hood scoop.

The scoop mated to a special air cleaner with a vacuum-actuated butterfly valve that funneled air directly into

the 735-cfm Holley four-barrel carburetor.

This Ram Air version could easily be identified by the "Shaker" hood

scoop, which was attached to the engine and protruded through the hood.

It shook, as the engine idled. Output was around 410 bhp,

but Ford only promised 335 bhp to calm insurance agents.

Both the Q and R engines were automatically promoted to Super Cobra Jet SCJ) status,

if a 3.91:1 or 4.30:1 rear axle ratio was ordered.

The SCJ got stronger internal engine components for better durability along with an external engine oil cooler

mounted in front of the radiator.

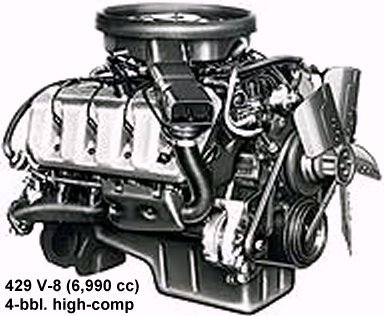

Z) 429 cubic inch (6,990 cc) V-8 high-compression engine with 4 barrel carburetor,

developing 335 bhp. This engine was found on the very rare and special 429 big Boss Mustang.

It had to use premium petrol only.

| The Bluffmaster convertible has the non-functional (decorative) air scoop on the hood. |

|

This scoop had built-in turn signal lamps in its rear. So when you looked through the windshield, you could see the turn signal repeater flashing in a recess in the rear of the hood scoop. |

The 1969 Mustang was 51 cm longer, longer, lower, meaner and sleeker than all previous Mustangs. Every dimension increased with the exception of wheel base, which remained at 108 inches (2,743 mm). All Mustangs were lowered 0.5 inch on the suspension and the windshield rake was increased by 2.2 degrees. This translated to about a 150-175 pound weight increase, depending on the model.

1969 was a high point year (and probably the best year) for the Mustang.

The 1969 Mustang introduced the exterior sports mirrors which were widely copied by other manufacturers.

The Bluffmaster Mustang has some incongruities.

It has the GT dummy scoop, but is wearing non-GT hubcaps on the styled steel wheels.

And it has just one ordinary flag mirror on the driver's side, instead of the body colored sports mirrors.

Also the white graphics on the side, modeled after the 1970 Boss 302 coupe is completely out of place on a 1969 GT convertible.

1969 was the first year for the radial tires option for the Mustang. And the intermittent windshield wipers option.

Massive effort went into modifying the basic Mustang to make the Boss 429 engine fit.

The engine claimed to put out 335 bhp (Ford's whispers), was capable of well over 400 bhp.

Visually, the Boss 429 sits lower than other 1969 SportsRoof Mustangs. And compared to the Mach 1 or Boss 302, it has an understated image.

Save for the Boss 429 fender decals and large hood scoop, the Boss 429 doesn't have any stripes, blacked-out trim, wheel or rocker panel moldings or even chrome dual exhaust tip outlets.

The Boss 429 Mustang was a limited production Mustang designed to homologate the Boss 429 engine for NASCAR racing.

The rules were that, to race an engine it had to be fitted to at least 500 production units that could be sold to the public.

This was called homologation.

So the Boss 429 was produced by shoe-horning by-hand, the big 429 cid engine into the Mustang SportsRoof bodies.

These

mods were done at the Kar Kraft facility in Brighton, Michigan -- the same facility that built Ford's Le Mans GTs.

Partially

completed SportsRoof Mustangs meant originally to receive the

428 SCJ engine, were modified at Kar Kraft to accept the giant 429

engine.

The Mustang's engine bay was 2" too narrow to accommodate the Boss 429 engine.

The shock towers were manually relocated outward and the suspension was lowered and moved further outwards one-inch,

using special Boss 429 specific, spindles and control arms.

This required completely new shock towers with a different shape, new widened strut tower brace,

new top and bottom suspension arms, new heavy duty uprights, and heavy duty springs.

A slim new power brake booster was needed to clear the big engine valve cover,

and the battery was moved to the trunk to improve weight distribution.

The front fenders were hand rolled, and the hood was hand fabricated for an oversized hood scoop.

This scoop would get a manually controlled intake flapper valve.

The rear suspension got a rear sway bar.

This made the Boss 429 handle much better than other big-block equipped Mustangs.

The rear suspension was beefed up with staggered shocks, HD springs, and a thick rear stabilizer bar.

The whole car sat an inch lower than a stock Mustang, and as a consequence, a special "short" front spoiler was fitted to preserve clearance.

Other features included:

All Boss 429s came with the Deluxe Decor interior, 8000 rpm tachometer and AM radio.

In production trim the engine was de-rated to produce only 375 bhp by using a mild hydraulic cam, a tiny carburettor, and smog pump.

The Boss 429 blocks have HP429 cast into the front of the block (driver's side).

It used four bolt mains, a forged steel crank and forged steel connecting rods.

What was the big deal?

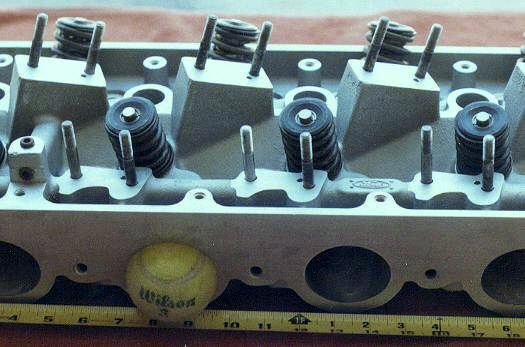

Aluminum cylinder heads with a modified Hemi type combustion chamber which Ford called "crescent".

Chevrolet engines were usually painted with Orange Engine Enamel, while Ford engines were painted Ford Blue!

Ford called this 429 hemispherical headed engine,

the Blue Crescent engine,

but as the intake and exhaust ports in the huge alloy heads were so large, mechanics call it the "Shotgun".

Its intake ports are almost large enough to accomodate a tennis ball!

The two massive aluminium alloy heads with hemispherical combustion chambers, have massive ports with huge 58.5 mm inlet valves.

-- the biggest that Ford has ever fitted into a production engine.

These heads used the "dry-deck" method, meaning no head gaskets were used.

Each cylinder, oil passage and water passage had an individual "O" ring to seal it.

The main block is of high strength cast iron.

It has four bolt main bearings, and forged steel cranks and connnecting rods.

The Boss 429 used a single Holley four-barrel carburetor rated at 735 CFM mounted on an aluminum intake manifold.

1969 camshafts had hydraulic lifters. 1970 models got a mechanical lifter camshaft along with an improved dual exhaust system.

In each Boss 429 Mustang, on the inside of the driver's door

above the black Ford Warranty Plate, was a silver KK (Kar Kraft) sticker with Kar Kraft's production number.

The first Boss 429 was numbered "KK 1201" while the last 1969 is numbered 2059.

Some Boss 429s may not have this silver tape stripe -- Kar Kraft substituted a small brass plate on a few cars.

Besides the Boss 302, the Boss 429 was the only other Mustang that had its Serial number stamped

Only 859 Boss 429s were built in 1969.

And only 499 were built in 1970!

1969 Boss 429 Mustangs were available in five colors:

1970 versions were painted:

Interior trim codes: TA black & TW white

All 1970 Boss 429s came with a gloss black painted hood scoop.

Notwithstanding its impressive specifications, the Boss 429 was not a street terror.

Unmodified, it it just about equaled the 428CJ performance.

However the usual after market bolt-on modifications really woke the engine up to its NASCAR pedigree.

By the end of the 1969 production run the story of the Boss 429 "Shotgun" Mustang had spread throughout all the Ford Dealers.

Demand was so high that another run of 500 1970 models was started in August 1969 and completed by December 1969.

Ford lost considerable money on each car due to the amount of manual rework required in the conversion.